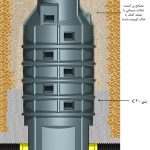

پلی اتيلن گريد 3840

در توليد مواد قالبگيري چرخشي عليالخصوص منهولها از پلياتيلن گريد 3840 که پلیمری است با خواص فوق العاده استفاده ميشود. در ايران اين ماده در پالايشگاههاي تبريز و اراك توليد ميشود.

در جدول ذيل مشخصات پلياتيلن توليد شده در پالايشگاههاي داخلي آمده است. شاخص MFR يا همان شاخص جريان مذاب برابر با 4 و چگالي اين نوع پلياتيلن برابر با 0.938 است.

Value | Unit | Property |

| 0.936-9.40 | (gr/cm3) | Density |

| 3.6-4.5 | (gr/10min)(2.16Kg,190⁰C) | MFR |

| ≥2 | (KPa) | Sn |

| ≥10 | (min) | OIT |

جدول 1 – مشخصات پلياتيلن توليدي در پالايشگاههاي داخلي

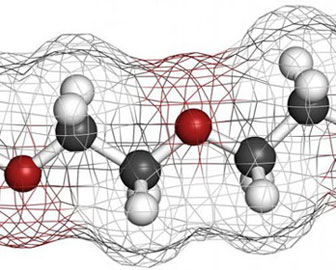

اين ماده قابل بازيافت بوده و زنجيره پليمري آن بسیپلياتيلن گريد 3840ار فشرده است، اين عامل سبب افزايش چگالي آن ميشود و در نتيجه مقاومت مکانیکی آن افزایش و فشردگي زنجيرههاي پليمري سبب مقاومت بالاي آن در برابر مواد شيميايي و تنشهاي شكننده محيطي ميشود.

اين ماده به صورت اوليه بيرنگ و غيرشفاف است و جهت استفاده ميتوان به آن رنگدانه افزود. سطوح داخلي و خارجي منهول بايد صاف، تميزو عاري از هر گونه نقص باشد. رنگ منهول ميتواند هر رنگي باشد، با اين حال رنگ بايد در سراسر سطح آن يكنواخت باشد.

مواد پلياتيلن 3840 توليدي در پالايشگاههاي داخلي داراي مواد افزودني پايداركننده حرارتي، نوري و رنگ است.

بر اساس استاندارد ملی 14148 ايران منهولهاي پلياتيلن شرکت پلیمر روشان شرايط ماندگاري در فضاي باز به مدت حداقل يكسال را داشته و بدين منظور مواد سازنده آن حاوي افزودنيهاي ضد پرتو فرابنفش می باشند.

محصولات شرکت پلیمر روشان دارای استاندارد 14148 از سازمان ملی استاندارد ایران به شماره پروانه 7672530974 میباشند.