بر اساس استاندارد ملی 14387 که خود مطابق با استاندارد ASTM 1759 تهیه شده است، منهول پلیاتیلن بایستی تحمل بارهای افقی (شعاعی) ناشی از فشار خاک اطراف و نیز بارهای عمودی (محوری) ناشی از وزن خاک و بارهای وارده بر آن را داشته باشد. بر این مبنا پرکننده اطراف منهول (Backfill) بایستی به ترتیبی تهیه و اجرا گردد که به همراه سازه پلیاتیلنی منهول توأمان این بارها را تحمل نموده، بدون اینکه در طول سالیان بهرهبرداری پایداری خود را حفظ نماید.

همچنين در صورتي كه خاك كف سست باشد و امكان كفسازي فراهم نباشد، ميتوان به جاي خاك از بتنهاي پيشساخته با ضخامت 15 سانتيمتر استفاده كرد.

این استاندارد، پرکننده اطراف منهول را از خاک class I با تراکم 90درصد و کف منهول را با تراکم 95درصد تعریف مینماید. این پرکننده دارای خواص الاستیسیته (عدم شکنندگی)، متراکم شده (unshrinkable) و دارای تحمل فشار حدود 0.8MPa است. از آنجاییکه تراکمدهی خاک اطراف منهول با توجه به اینکه نمیخواهیم خاک دست نخورده اطراف را زیاده از حد برداشت کنیم، براحتی مقدور نیست؛ لذا میبایست از ملات جایگزین استفاده نماییم.

مصالح پرکننده: (Backfill)

1- خاک Class I

مطابق تعریف استاندارد

2- ملات شفته آهک:

در صورت وجود خاک مناسب در محل و جدا کردن سنگ و قلوههای درشت آن میتوان براحتی از این ملات استفاده نمود که مشابهت زیادی با تعاریف استاندارد داشته و به هیچ عنوان بر روی منهول پلیاتیلن واکنش شیمیایی و یا خوردگی انجام نمیدهد.

3- ملات سیمانی:

انجمن سیمان آمریکا در معرفی ملات سیمانی پرکننده (Backfill) نوعی ملات سیمانی را معرفی نموده است که در جاهای مختلف با عیارهای متفاوت کاربری دارد، مانند پشت فونداسیونها و یا اطراف منهول و … که به آن CLSM میگویند. این ملات پرکننده مناسب اطراف (CLSM) صرفا یک ملات سیمان بوده و به هیچ وجه بتن محسوب نمیشود، زیرا عیار آن در حدود 80Kg/m3 -70 است و دارای خواص زیر است:

1- قابلیت الاستیسیته دارد. (Elasticity)

2- خودمتراکم شونده است. (Self-Compact)

3- کاهش حجم ندارد. (Unshrinkable)

4- به هیچ عنوان شکننده نیست.

5- تحمل فشار حدود 0.6MPa-0.4 دارد.

6- مقاومت فشاری 0.1MPa بعد از یک روز.

7- مقاومت فشاری 0.5MPa بعد از 28 روز.

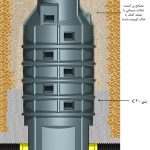

شماتیک کلی نصب منهول به همراه مواد و مصالح مورد نیاز

ترکیب مواد متشکله ملات سیمانی (CLSM)

| شن (تا 19 میلیمتر) | Kg/m3 1010 |

| ماسه | Kg/m3 1150 |

| آب | Kg/m3 155 |

| سیمان | Kg/m3 45 |

نحوه پر کردن اطراف منهول:

پس از نصب و انجام اتصالات منهول و همچنین تراز کردن آن میبایست مواد پرکننده بصورت لایه لایه و بطور مساوی در اطراف منهول ریخته شود تا راستای قائم منهول حفظ و از یکنواخت بودن پرکننده و بدون حفره بودن آن اطمینان داشت. از ریختن یکباره مواد پرکننده جدا خودداری نمایید.

استفاده از کمپکتور جهت کوبیدن خاک اطراف منهول

کفسازی :

برای استقرار منهول بایستی بستری نسبتا محکم فراهم آورد، لذا برای اینکار ابتدا کف محل گودبرداری را از قلوه سنگهای درشت تمیز نموده و با کمپکتور کفکوبی و صاف مینماییم. در صورتیکه این امکان وجود نداشته باشد بایستی حداقل 10 سانتیمتر بتن مگر اجرا نموده و نشیمن منهول را یکدست نماییم.